ABOUT TSUNAMI

At Tsunami, we are more than just a manufacturer of waterproof hard cases - we serve as your strategic ally in safeguarding your valuable equipment from the elements. With a legacy of excellence spanning decades, Tsunami has established itself as synonymous with reliability, innovation, and unwavering quality in the realm of protective gear solutions. For over 15 years, Tsunami has been providing professional carrying and transport solutions for professionals, technicians, sports enthusiasts, and more, protecting their value and passions worldwide.

Development

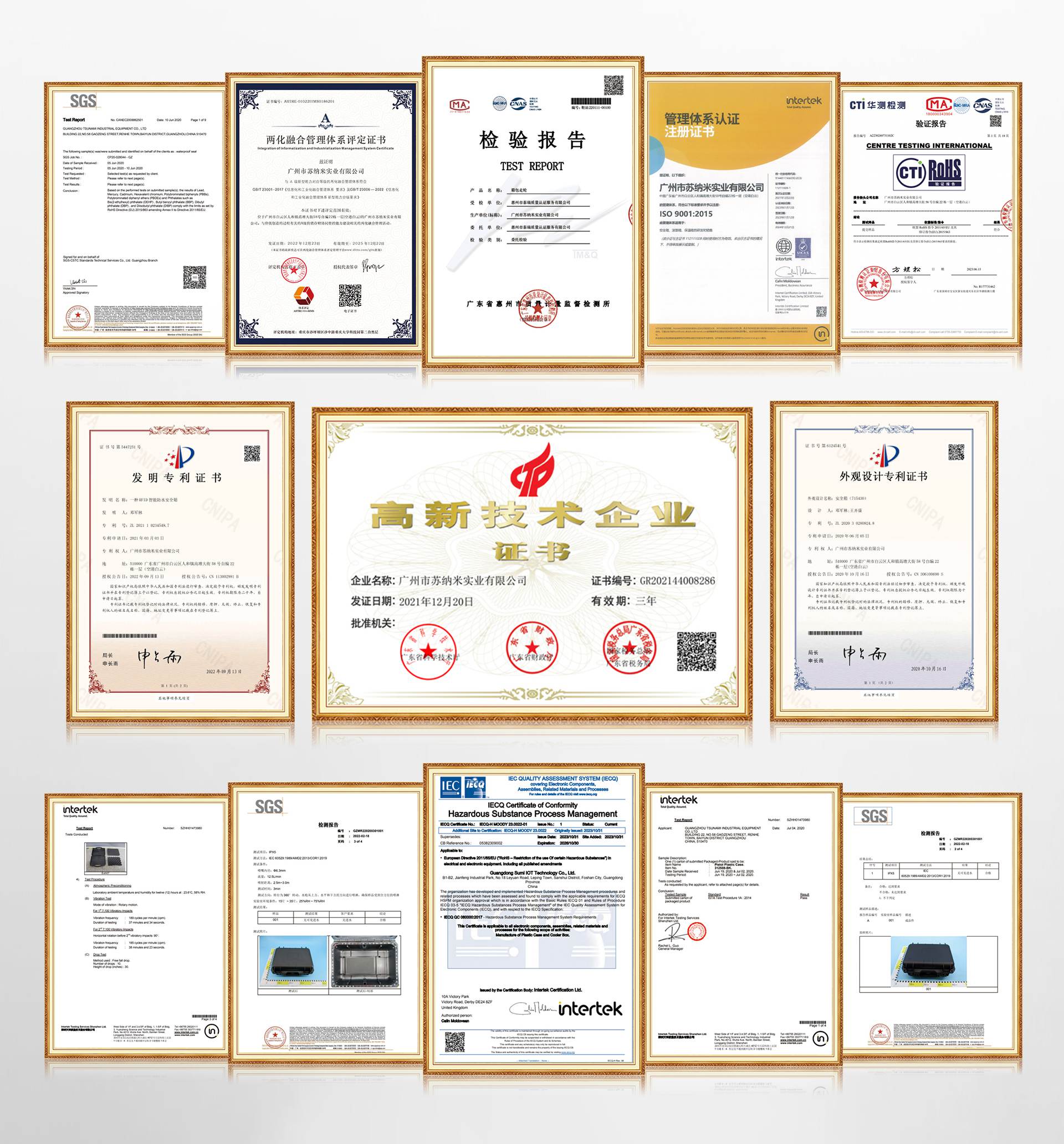

With its outstanding technical strength and production capacity, Tsunami has obtained hundreds of patents and certificates, and its protective cases are sold worldwide. The company has passed ISO9001 system certification and product quality certification from institutions such as COC/SGS to ensure product quality and customer satisfaction. With professional technical strength, innovation ability, and strict quality control, Tsunami has become a leader in the field, promoting the development of the entire industry and providing reliable products and services.

Production

Our injection molding workshop is equipped with 24 injection molding machines and 1 automatic gluing machine, of which the lightest injection molding machine weighs 90 tons, and the heaviest reaches 2000 tons. These machines are capable of producing about 20,000 plastic pieces per day. To further improve production efficiency, our company introduced robotic arms and automated production systems, resulting in a 15% increase in overall production efficiency, which not only greatly reduces customer waiting time, but also significantly improves work efficiency.

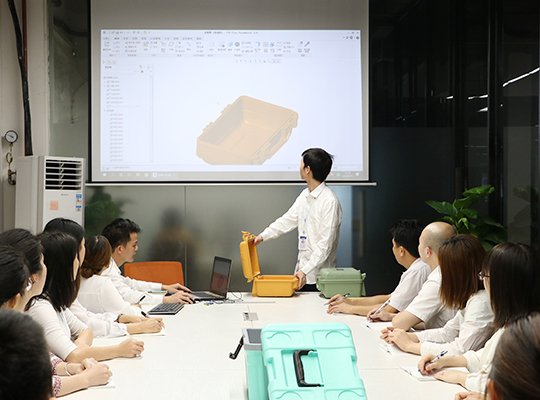

Tsunami is dedicated to researching and developing transportation solutions, making substantial investments in the development of unique patented technologies and production processes. As a professional manufacturer of cases, we have assembled a top-notch team of technical specialists in molding and injection molding within the industry. Each Tsunami case is crafted in our cutting-edge manufacturing facility through a rigorous production process that involves precision engineering and state-of-the-art technology. Our factory utilizes the highest quality materials and advanced manufacturing techniques to ensure that each case meets stringent durability and performance standards.

Our team of experienced craftsmen and engineers is dedicated to bringing your vision to reality, from design concept to final product assembly. With meticulous attention to detail and unwavering commitment to excellence, we oversee every step of the production process to ensure the highest level of quality control.

Tsunami is a professional case manufacturer with a bunch of top technicians in molding and injecting industry.

After years of development, Tsunami Factory relocated to a larger facility in 2019, spanning over 30,000m2. We boast an extensive array of advanced equipment including grinding machines, milling machines, EDM, CNC and our own mold department housing over 1,500 sets of molds, half of which are large molds. Additionally, we operate 25 pcs injection molding machines with a daily production capacity exceeding 15,000 pieces.

Upon completion of molds and production, all products undergo rigorous testing in our dedicated laboratory center. Tsunami is dedicated to delivering flexible and multifunctional solutions for customers seeking the perfect plastic casing, encompassing design, processing, testing and production. Simply share your creative ideas and provide us with the case draft or foam draft – we will develop new designs and customized foam inserts tailored to your requirements.

The Tsunami case is engineered to thrive in the most extreme environments, boasting durability, waterproofing, shockproofing, pressure resistance, sand and dust protection, as well as anti-corrosive properties. These cases are meticulously designed to safeguard and transport delicate items such as industrial and medical equipment, electronics, cameras and video equipment, musical instruments, drones, outdoor gear, military and firefighting equipment. Featuring customizable foam inserts, ergonomic handles and a secure locking mechanism for added convenience and peace of mind. Wherever your adventures take you, trust Tsunami to keep your gear safe every step of the way!

As a professional hard plastic case manufacturer, we are committed to providing high-quality products and services to protect customer value. Meanwhile, we promise to protect your interests and enthusiasm with a lifetime warranty.

Tsunami, as the guardian of your valuable equipment, is a solid bulwark against natural disasters. We specialize in the production of waterproof hard cases and have earned a good reputation for our excellence in protecting equipment from extremely harsh environments.

Tsunami Certifications

Since its establishment, Tsunami has achieved fruitful results in patents, software copyrights and certification certificates through continuous R&D innovation and technology accumulation. Among them, there are 74 patents, 15 software copyrights, and 6 authentication certificates.